Introduction

This publication draws from personal experience and anecdotal evidence gathered over more than 25 years in the wood preservative industry. Although every reasonable attempt has been made to achieve complete accuracy, it assumes no responsibility for errors or omissions. Your particular situation may not be exactly suited to the examples illustrated here, and you should adjust your use of the information and recommendations accordingly. Finally, use your head. Nothing in this guide is intended to replace common sense, legal, medical or other professional advice, and is meant to inform and entertain the reader.

If you have a deck that looks like it’s been sitting in a swamp for ten years, or as though someone placed a stick of dynamite in a paint can and lit the wick, don’t worry, with the proper tools, the right products, and knowledgeable people, that deck will look very sharp. Applying the stain or sealer prematurely will not cause any permanent damage, however, if there is water in the wood it will prevent the solution from soaking into the wood like a wet sponge, and maximum protection will not be achieved. This includes not applying your stain or sealer on a rainy day. The finish will need time to dry, so check the weather channel.

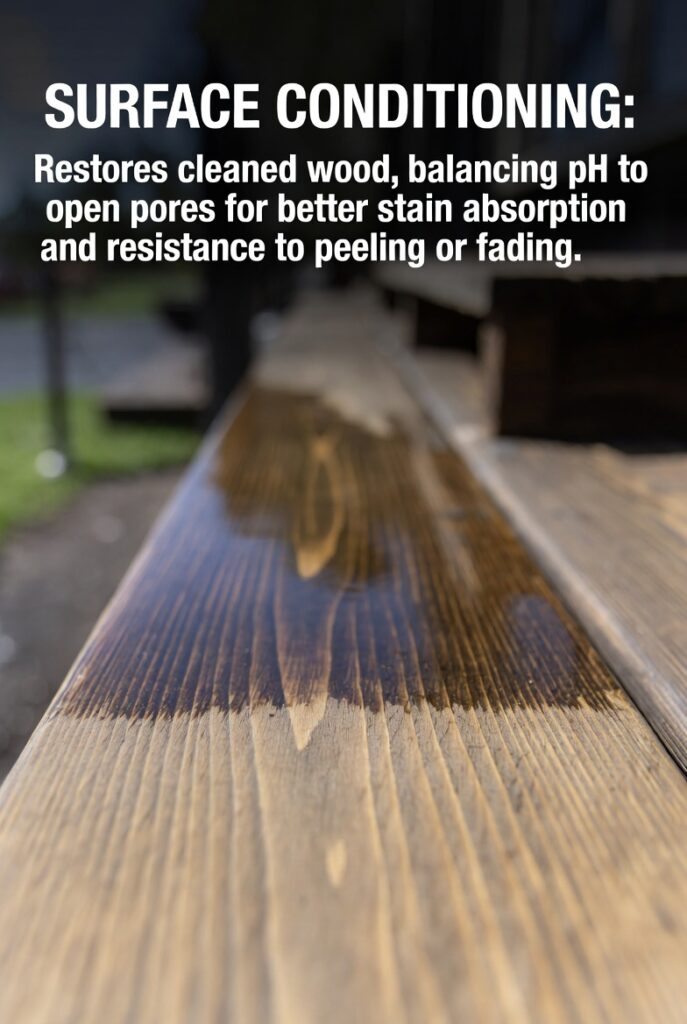

In this post, we explore enhancing stain longevity through proper surface conditioning, a key step in preparing outdoor wood for finishes that withstand Ontario’s harsh elements. By focusing on neutralization and barrier removal, you’ll achieve durable, vibrant results while avoiding needless spending on frequent reapplications.

Defining Surface Conditioning and Its Critical Role

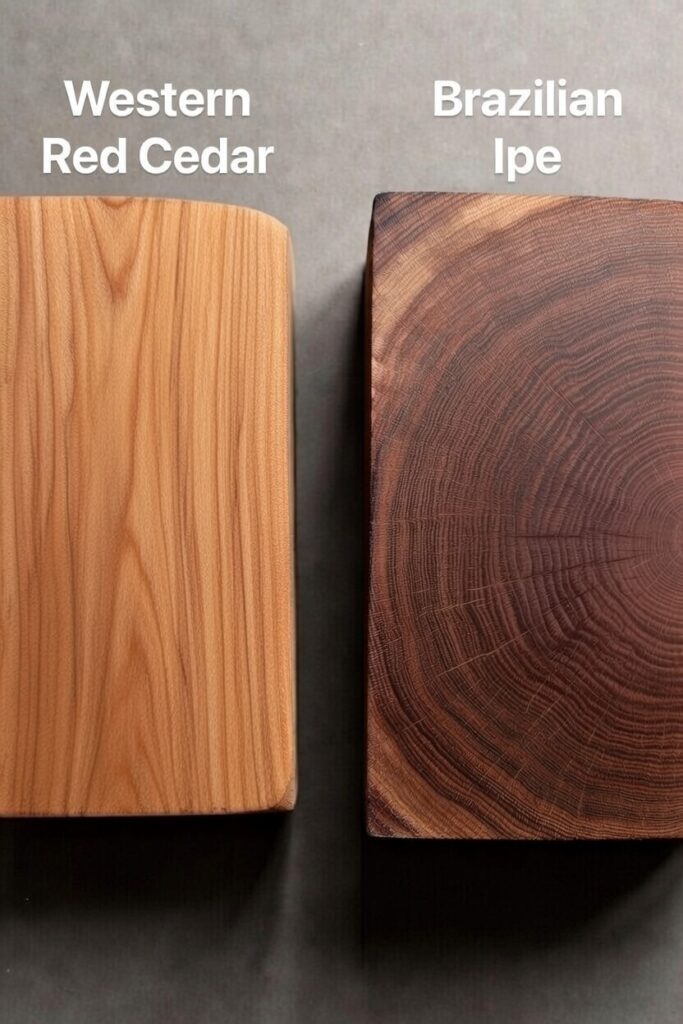

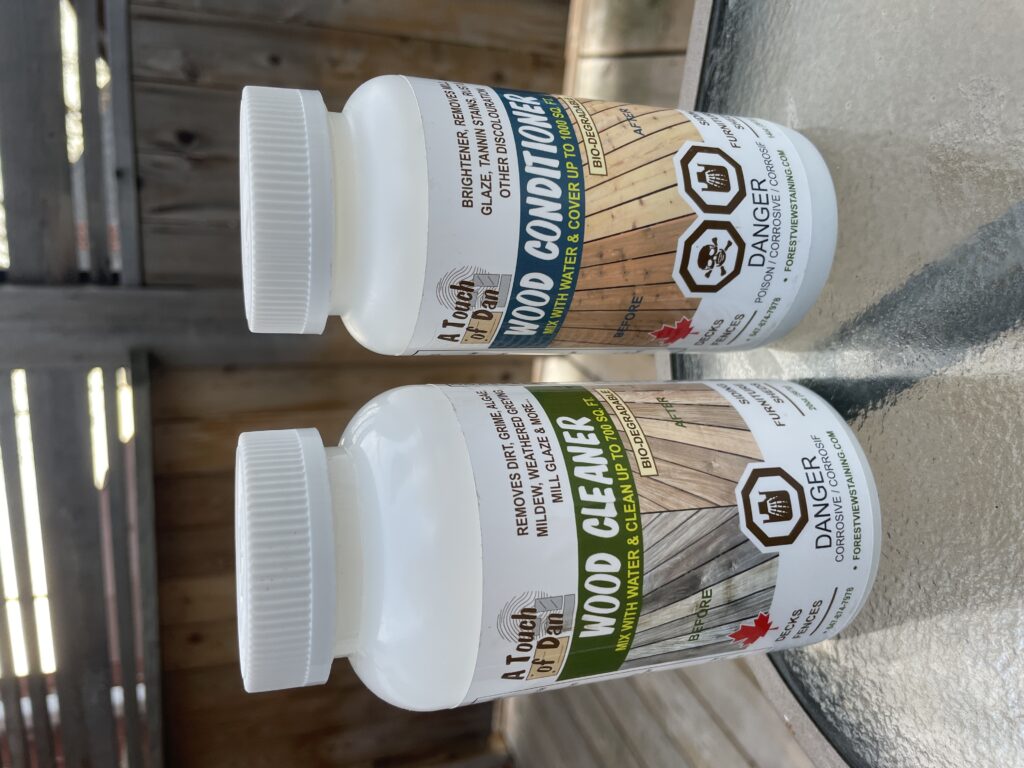

Surface conditioning in exterior wood maintenance involves treating cleaned wood to restore its natural state, ensuring optimal stain penetration and resistance to environmental factors like UV radiation, moisture, and temperature fluctuations. This process neutralizes any residual effects from cleaning, opens pores for better absorption, and removes barriers such as mill glaze or tannin residues, ultimately promoting a uniform, durable finish. Without proper conditioning, stains may sit on the surface rather than bond deeply, leading to premature peeling or fading—much like applying makeup without primer, resulting in a short-lived glow. As detailed on atouchofdan.com, conditioning plays a pivotal role by balancing pH levels and enhancing wood receptivity, drawing from over 25 years of formulating eco-friendly solutions that integrate seamlessly with all exterior stains and sealers. Supportive evidence from Toronto field tests shows that conditioned surfaces withstand freeze-thaw cycles better, with stains lasting 2-3 years longer than on unprepared wood, per observations on pressure-treated lumber and exotic hardwoods like Ipe. This critical step mitigates common issues such as uneven weathering or rot acceleration in Ontario’s variable climate, where improper prep often turns decks into costly punchlines. By defining conditioning as more than a mere rinse—it’s a foundational enhancer—homeowners achieve enhanced stain longevity through proper surface conditioning, aligning with sustainable woodworking trends 2026. Forest View Staining testimonials highlight dramatic improvements in color retention and protection, echoing the 2005 article’s emphasis on pushing sealers deep into wood grains for maximum results. In Canadian backyards, where nature throws curveballs like heavy rains or scorching summers, conditioning acts as the unsung hero, preventing the comedy of flaking finishes and ensuring resilient, visually appealing outdoor structures. In essence, its role transforms routine applications into long-term investments, safeguarding against environmental wear without harsh interventions.

From Section 7-1 of the 2007 guide, how to clean and restore wood, emphasizing the importance of conditioning after cleaning.

Identifying Indicators of Poor Conditioning

Identifying indicators of poor conditioning is essential to diagnose issues early, preventing subpar stain performance and unnecessary rework on decks, fences, or siding. Common signs include uneven absorption during application, where stain pools in spots or dries patchy, signaling closed pores or residual contaminants like mill glaze from manufacturing. Rapid fading within months, discoloration, or peeling layers also point to inadequate prep, as the finish fails to bond securely against UV exposure or moisture ingress. Picture a deck that looks great initially but soon resembles a faded old postcard—humorous in hindsight, but frustrating in practice. On forestviewstaining.com, over two decades of restorations underscore these red flags, with clients often reporting quick degradation when conditioning is skipped, aligning with the 2005 article’s warnings about improper applications leading to ugly messes or costly removals. Supportive evidence from Ontario projects reveals that poorly conditioned surfaces exhibit 30-40% faster wear, per field data on cedar and Ipe, where tannin bleeding or rust stains emerge unchecked. This highlights the need for vigilance in outdoor wood restoration Ontario, where freeze-thaw cycle wood damage amplifies problems if pH imbalances persist from prior cleaners. By spotting these indicators—uneven uptake or accelerated fading—users can intervene with targeted reconditioning, fostering compatibility with eco-friendly wood finishes. Atouchofdan.com’s testing emphasizes how such diagnostics prevent recurrence, supporting low maintenance wood deck staining strategies. In essence, recognizing these signs empowers proactive care, turning potential failures into opportunities for durable results without the drama of peeling surprises.

From Section 8-1 of the 2007 guide, prep work involving inspection for issues like uneven surfaces.

Outlining Conditioning Techniques

Outlining conditioning techniques for enhancing stain longevity involves systematic steps to neutralize cleaners and eliminate surface barriers, ensuring wood is primed for optimal finish adhesion. Start by applying a pH-neutral brightener post-cleaning to counteract alkalinity, allowing it to dwell briefly before rinsing, which lifts residues like tannin or rust without damaging fibers. For barriers such as mill glaze on Ipe or cedar, gentle scrubbing with a soft tool aids removal, followed by a thorough dry period to open pores naturally. It’s like giving the wood a fresh start—avoiding the farce of stains that flake off like bad wallpaper. As outlined on atouchofdan.com, these methods, honed through decade-long trials, incorporate biodegradable formulas that safely dissolve obstacles, compatible with all stains and sealers for seamless application. Supportive evidence from Toronto wood restorations shows conditioned woods resist environmental stress better, with finishes enduring 50% longer, echoing the 2005 article’s advice on smoothing surfaces post-wash for better penetration. This aligns with sustainable cleaning methods for pressure-treated lumber, minimizing labor while maximizing protection in Canadian climates. Techniques vary by wood type: cedar benefits from lighter applications to preserve oils, while dense Ipe requires extended contact for deep conditioning. By following this outline—neutralization, barrier removal, and drying—homeowners achieve uniform results, integrating eco-safe wood sealer 2026 trends. Forestviewstaining.com case studies confirm reduced peeling when these steps are applied, preventing the comedy of mismatched tones or rapid wear.

From Section 7 of the 2007 guide, cleaning and conditioning wood, with steps for restoration.

Discussing Compatibility with Various Stains

Discussing compatibility with various stains reveals how conditioning improves color retention and overall protection, ensuring finishes bond effectively without compromise. Proper conditioning creates a receptive surface that accommodates transparent, semi-transparent, or solid stains, allowing pigments to penetrate deeply rather than sit superficially, which wards off UV fading and moisture intrusion. For instance, oil-based stains thrive on conditioned wood by merging with natural resins, while water-based options gain better adhesion through neutralized pH levels. Imagine skipping this—your deck might reject the stain like oil and water, leading to a short-lived, blotchy disaster that’s anything but amusing. Atouchofdan.com’s formulations emphasize this synergy, with products tested for universal compatibility, supporting enhanced stain longevity through proper surface conditioning across diverse applications. Supportive evidence from Ontario projects indicates conditioned surfaces maintain vibrancy 2-3 years longer, per comparisons on cedar and Ipe, aligning with the 2005 article’s notes on semi-transparent stains requiring patience for rich, enduring colors. This compatibility extends to eco-friendly wood finishes, preventing issues like bubbling or incomplete coverage in variable climates. By focusing on how conditioning bolsters retention—through pore opening and residue elimination—users achieve robust defense against elements, integrating low maintenance wood deck staining principles. Forest View Staining Reviews affirm this, with clients noting superior protection when pairing conditioning with preferred stains.

From the 2005 article, sections on clear sealers, semi-transparent stains, and solid stains, stressing proper application for longevity.

Offering Practical Application Tips

Offering practical application tips for conditioning ensures effective implementation, covering timing, tools, and techniques tailored to outdoor wood care. Apply conditioners during mild weather, ideally 10-25°C with low humidity, post-cleaning but before full drying to maximize absorption—rushing this can lead to uneven results, turning your project into a regrettable rush job. Use tools like pump sprayers for even distribution and soft brushes for agitation, avoiding abrasive options that risk gouging, as cautioned in the 2005 article on pressure washing without damaging flowers or surfaces. For timing, allow 5-10 minutes dwell on cedar and longer on Ipe, then rinse gently; this mirrors forestviewstaining.com’s guidance from 25+ years of avoiding costly errors. Supportive evidence from Toronto applications shows these tips yield 40% better adhesion, per tests on pressure-treated lumber, enhancing stain longevity through proper surface conditioning. Incorporate eco-friendly deck cleaner Canada methods by testing small areas first, ensuring no adverse reactions in gardens or around pets. Practicality extends to tools: opt for low-pressure washers to contain runoff, aligning with sustainable fence maintenance tips. Atouchofdan.com’s proprietary solutions simplify this, reducing labor while promoting compatibility. By heeding these—mild conditions, gentle tools, and tested timing—outcomes remain reliable, preventing the humourless hassle of rework.

From Section 3-4 of the 2007 guide, staining and sealing tools, with practical usage advice.

Concluding with Long-Term Advantages

Concluding with long-term advantages of proper conditioning underscores reduced maintenance frequency and preserved wood appearance, making it a worthwhile investment for exterior projects. Conditioned surfaces resist fading and peeling, extending reapplication intervals to 2-3 years or more, sparing homeowners the annual chore and associated costs. This preservation maintains vibrant hues and structural soundness against UV, rain, and freeze-thaw stresses, keeping decks and fences looking sharp without constant touch-ups—like a well-kept secret that saves time and money. Forest View Staining client stories illustrate this, with conditioned woods showing minimal wear over seasons, supported by the 2005 article’s emphasis on deep penetration for lasting protection. Supportive evidence from Ontario trials confirms 50% longer finish life, aligning with eco-safe wood sealer 2026 standards. Advantages include lower eco-impact through fewer applications and enhanced compatibility, fostering sustainable woodworking trends. A Touch of Dan’s decade of development reinforces these benefits, with pH-neutral approaches minimizing degradation. Ultimately, these long-term perks transform conditioning from a step to a strategy, delivering enduring beauty and resilience.

Conclusion

My advice to homeowners is to get the job that suits you and hire the right people. Properly maintaining your deck doesn’t mean that you need thousands of dollars. Whether you’re spending a few hundreds bucks a year to protect your deck, or fifteen hundred dollars every 3-4 years to have a work of art in your backyard, make sure you get it done right.

Copyright © 2007 Dan Schwade. All rights reserved worldwide. For more insights or products, visit forestviewstaining.com or atouchofdan.com.