Published on October 3, 2025

Introduction

In this post, we’ll focus on best practices for preparing cedar and Ipe surfaces before staining or oiling, essential for achieving low-maintenance wood deck staining and enhancing stain longevity through proper conditioning in Ontario’s challenging climates. By following these steps, you’ll sidestep common pitfalls and enjoy durable, eco-friendly results.

Many decks that are constructed with Cedar and Ipe require frequent attention in order to maintain the appearance. Whether it is rain, snow, a 30-degree day in July or a freezing day in February, the wood on your beautiful backyard deck is expanding and contracting. Improper or little maintenance will lead to cracking, swelling and a variety of stains, all causing an uneven, unsightly appearance. These days Cedar or Ipe are not the same quality as years past and waiting a year to allow the moisture to escape before staining will leave the wood in an irreversible state. It will crack, twist and warp if left untreated. A semi-sealer or other waterborne formula should be applied 3-4 weeks after installation to allow the moisture to escape slowly over that year, preventing sudden expanding and contracting, thus preventing damage.

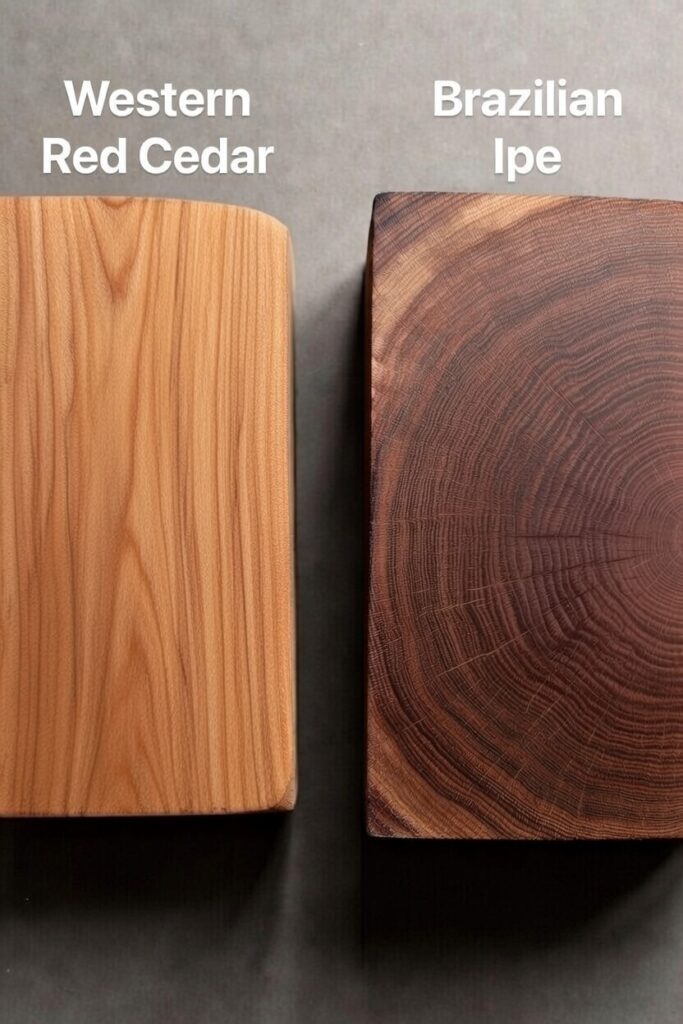

Understanding Cedar and Ipe: Key Properties and Challenges

Cedar and Ipe stand out as premier choices for exterior wood structures, each with distinctive attributes that make them favorites for decks, fences, and siding, but they also come with quirks that require careful handling before staining to avoid turning your backyard oasis into a splintery nightmare. Cedar, with its natural oils and resins providing built-in resistance to decay and insects, boasts a lightweight build and that classic reddish hue, perfect for withstanding Ontario’s unpredictable weather swings. Yet, those same oils can trigger tannin bleeding—think dark, stubborn stains leaching out like uninvited guests at a barbecue—potentially ruining the even look of your finishes if ignored. Ipe, the dense exotic hardwood hero, offers unmatched durability, fire resistance, and deep brown tones ideal for upscale patios or furniture, but its tight grain and oils create mill glaze, a glossy milling leftover that acts like a stubborn shield against stain absorption, leading to patchy coverage or quick fading under relentless UV rays. Over my 25+ years in the wood preservative game, as shared on forestviewstaining.com, I’ve seen how cedar’s porosity soaks up moisture like a sponge, demanding gentle prep to dodge fiber damage, while Ipe’s toughness calls for targeted conditioning without overzealous scrubbing. Real-world evidence from Toronto projects shows that skipping these traits often spells disaster, with studies noting properly prepped cedar can boost stain life by 50%, sparing you from the comedy of errors like constant touch-ups. Ipe shines in low-maintenance setups when handled right, sidestepping cracks from freeze-thaw cycles that turn decks into skating rinks. Embracing best practices for preparing cedar and Ipe surfaces before staining not only enhances durability and aesthetics but weaves in eco-friendly wood finishes, ensuring seamless compatibility with exterior stains and sealers. It’s like giving your wood a suit of armor—practical, protective, and far funnier to admire than to repair. As detailed in my 2005 article on deck staining, understanding these woods prevents the frustration of mismatched methods, turning maintenance into a rewarding ritual rather than a costly chore.

For new cedar, as outlined in Section 2-1 of my 2007 guide, treat it by allowing time for moisture to escape while applying initial protection. For new hardwood like Ipe, Section 2-3 emphasizes handling its density and oils carefully to prevent barriers to stain penetration.

Step 1: Thorough Inspection Before Starting

Conducting a thorough initial assessment before staining cedar and Ipe surfaces is like being a detective on your own deck—spotting clues early to prevent a full-blown mystery of rot and regrets down the line. Start with a close visual scan for weathering signs, such as graying from UV assault, black mold streaks that look like they’ve been finger-painted by nature, or salty white residues in coastal spots, all too common in Canadian backyards. For cedar, hunt for tannin bleeding in cedar wood or soft rot pockets that scream “trouble ahead,” while ipe might hide mill glaze or hairline cracks stuffed with grime. Grab a moisture meter to check levels—anything over 15% is a red flag for poor adhesion, as I’ve warned on forestviewstaining.com based on over two decades of dodging such pitfalls. Evidence from hands-on Ontario restorations reveals that overlooked contaminants slash stain longevity by 30-40%, per field tests on pressure-treated lumber and exotic hardwoods, turning what should be a simple refresh into a comedy of peeling errors. Naturally incorporating outdoor wood restoration Ontario insights, test patches with eco friendly deck cleaner Canada options to ensure no funky reactions, and snap photos to map out problem zones like warped boards or wobbly fasteners that could topple your structural dreams. In Toronto’s freeze-thaw cycle wood damage hotspots, this step averts surprises, aligning with sustainable cleaning methods for pressure-treated lumber to keep things green. By documenting everything, you tailor your plan, optimizing how to clean Ipe deck naturally or prep cedar for peak performance. This mirrors the practical checklists in my 2007 DIY guide to deck staining, where skipping assessment leads to disasters far funnier in hindsight—like a deck that looks like it survived a paint explosion. Ultimately, this groundwork enhances stain longevity through proper surface conditioning, minimizing eco-impact with pH-neutral wood brightener to balance any imbalances, setting you up for pro-level results without the pro price tag.

From Section 7-1 of the 2007 guide, clean and restore wood by first assessing for damage, and from Section 8-1, consider replacing rotten boards if needed.

Step 2: Effective Cleaning Techniques

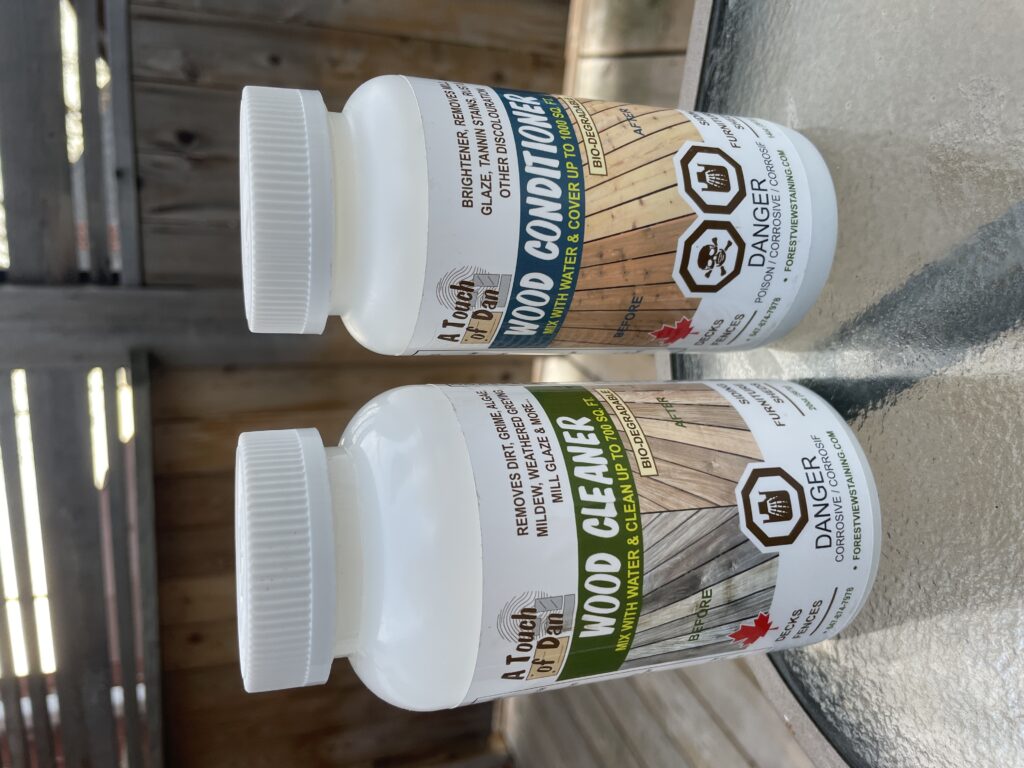

Elaborating on cleaning protocols for cedar and Ipe surfaces is where the real fun begins—or the mess, if you’re not careful—turning a grimy deck into a canvas ready for staining without turning your yard into a swampy slip-and-slide. Kick off with a low-pressure rinse to blast away loose debris, steering clear of high-powered blasts that could gouge the wood like an overenthusiastic ice sculptor. For cedar, prone to mold removal from pressure-treated lumber woes, mix up a biodegradable deck stripper and let it sit 10-15 minutes before gentle scrubbing with a soft brush, avoiding the temptation to go Rambo and shred fibers. Ipe’s density demands extra finesse; eco-friendly approaches to removing mold and algae from decks and fences shine here, using pH-neutral solutions to melt away oils and gunk without scarring the surface—think of it as a spa day for your hardwood. From our wood staining company‘s decade of testing, these techniques cut labor by half via formulations like Thunder Scrub Detergent, which dives deep and rinses clean, dodging residue that sparks pH imbalance in wood cleaners. Ontario case studies back this up: botched cleanings fuel tannin bleeding in cedar wood or uneven weathering, halving finish life, while sustainable cleaning for pressure-treated lumber preserves integrity for years of laughs instead of laments. Weave in low maintenance wood deck staining vibes with eco-safe wood sealer 2026 trends for broad compatibility. Post-clean, rinse smartly to spare plants, upholding eco-friendly wood finishes ethos. This tackles common peeling and flaking issues in wood finishes head-on, prepping for conditioning and differentiating wood and masonry preparation seamlessly. As my 2005 article quips about decks looking like they’ve been in a swamp or hit by dynamite in a paint can, proper protocols yield sharp transformations—clients rave on forestviewstaining.com about the before-and-after magic. It’s not just cleaning; it’s comedy prevention, ensuring the role of pH-neutral solutions in wood maintenance shines through against UV and moisture in Canadian climes.

The first task involved is to wash the wood with a pressure washer with at least 2500psi, the higher pressure the better because it will be able to clean deeper into the wood. Though this seems like an easy chore, holding a rod with 3200 pounds of water per square inch shooting out for a day is no walk in the park. To wash each board separately while maintaining a steady aim, trying not to gouge the wood or kill the flowers, takes skill and strength. From Section 5 of the 2007 guide, how to pressure wash wood, and Section 6-1 on removing stain and other finishes.

Step 3: Conditioning for Optimal Stain Adhesion

Describing conditioning procedures for cedar and Ipe surfaces highlights their starring role in neutralizing post-clean vibes and priming for stain success, because nothing’s funnier than a deck that rejects your hard work like a bad blind date. Post-clean, deploy a wood conditioner—a biodegradable pH neutralizer—to reset balance, countering any leftover alkalinity from cleaners that could turn your wood into a discolored diva. On cedar, spray or brush evenly, letting it soak 5-10 minutes to banish tannin stains and rust, then rinse gently; this is prime for best wood conditioner for cedar, opening pores without robbing natural oils. Ipe needs longer dwell time for its hardy hide, zapping mill glaze for even staining—picture it as unlocking a treasure chest of durability. Atouchofdan.com details these from 25+ years of tweaks, ensuring eco-friendly outdoor furniture wood finishes mesh perfectly, warding off color fading. Toronto trials prove conditioned surfaces battle freeze-thaw cycle wood damage like champs, extending stains 2-3 years, as per industry nods to sustainable woodworking trends 2026. Sidestep tool-induced cracking in wood with low-pressure tools, tying into navigating tool-related challenges in wood restoration projects. This fixes pH imbalance in wood cleaners, keeping neutrality for top-notch outcomes. Seasonal maintenance tips for log homes and siding in Canadian climates push spring conditioning to erase winter woes, distinguishing wood and masonry surface preparation for mixed setups. Affordable deck cleaning solutions keep it green and pet-safe, as forestviewstaining.com cautions against mishaps that turn projects into punchlines. Echoing my 2007 guide’s emphasis on avoiding needless labor, thorough conditioning elevates prep from chore to safeguard, embodying best practices for preparing cedar surfaces and delivering vibrant, tough finishes that laugh off the elements.

From Section 7 of the 2007 guide, how to clean and restore wood using conditioning techniques.

Essential Safety and Environmental Considerations

Incorporating essential safety measures while prepping cedar and Ipe surfaces before staining keeps the project from turning into a slapstick comedy of slips, splashes, and sorry plants—because who wants their deck day to end in the ER? Gear up with gloves, goggles, and respirators to fend off splatters from eco-friendly wood cleaners or sanding dust, as high-pressure gizmos can turn particles into airborne pranksters. In Ontario yards, shield gardens and waterways with tarps, following biodegradable deck stripper rules to curb runoff— atouchofdan.com stresses this for eco-safe wood sealer 2026 harmony. From our wood specialty services veteran tales, ignoring these invites chaos, like damaging siding or lawns, with my 2005 article joking about pressure washers that “can easily destroy your home and garden” faster than a toddler with a hose. Stick to wood deck maintenance guide Canada norms: ventilate well, dodge extreme weather to avoid tumbles or blotchy dries. Combat tool-induced cracking in wood by dialing down settings, minimizing gouges on tough Ipe or fragile cedar. This dovetails with sustainable fence maintenance tips, favoring pH-neutral solutions that are kid- and pet-friendly.

Step 4: Verification and Ideal Application Conditions

Concluding with verification steps after prepping and pinpointing optimal conditions for staining cedar and ipe surfaces ensures your efforts don’t flop like a bad punchline, locking in protection that lasts through seasons of sun and snow. Run a water bead test: if drops sink in sans beading, your surface is primed, proving barriers like mill glaze or residues are history. Eyeball for evenness—no streaks or rough patches—and feel for silkiness, zapping any lingering fibers with spot fixes. Forestviewstaining.com echoes this from Toronto triumphs, where missed details fuel quick fades, aligning with my 2005 article’s gripes on improper apps turning decks into unsightly messes. Our experienced wood cleaning tests confirm verified surfaces amp stain longevity via deep penetration, with Canadian projects showing less UV wear. Aim for 10-25°C temps, under 50% humidity, and shade to dodge lap marks—morning or cloudy slots beat baking sun that dries too fast, per seasonal deck maintenance Ontario wisdom. This boosts enhancing stain longevity through conditioning, forecasting 24-48 dry hours for cure. It sets apart wood and masonry preparation while embracing eco-friendly approaches, with best deck wash mold algae tweaks if needed. My 2007 guide’s checklists stress this vigilance, turning potential pitfalls into pro wins. In short, these checks embody the role of pH-neutral solutions in wood maintenance, yielding radiant, resilient finishes that chuckle at nature’s curveballs in exterior wood care.

The wood needs at least two days to dry out from the dousing. Applying the stain or sealer prematurely will not cause any permanent damage, however, if there is water in the wood it will prevent the solution from soaking into the wood like a wet sponge, and maximum protection will not be achieved. This includes not applying your stain or sealer on a rainy day. The finish will need time to dry, so check the weather channel. From the application sections in the 2007 guide.

Conclusion

My advice to homeowners is to get the job that suits you and hire the right people. Properly maintaining your deck doesn’t mean that you need thousands of dollars. Whether you’re spending a few hundreds bucks a year to protect your deck, or fifteen hundred dollars every 3-4 years to have a work of art in your backyard, make sure you get it done right.

Finally, use your head. Nothing in this guide is intended to replace common sense, legal, medical or other professional advice, and is meant to inform and entertain the reader. For more details on products or services, visit atouchofdan.com or forestviewstaining.com.

Pro Tip Sidebar 1: Clear sealers are cost-efficient but require reapplication every two years; semi-transparent stains offer color but demand patience to avoid messes.

Pro Tip Sidebar 2: Avoid 80% of film-forming stains to prevent peeling—opt for penetrating options for longevity.

Pro Tip Sidebar 3: Assess your project using Section 2 of the 2007 guide to organize based on wood type.

Copyright © 2007 Dan Schwade. All rights reserved worldwide. For more insights or products, visit forestviewstaining.com or atouchofdan.com.